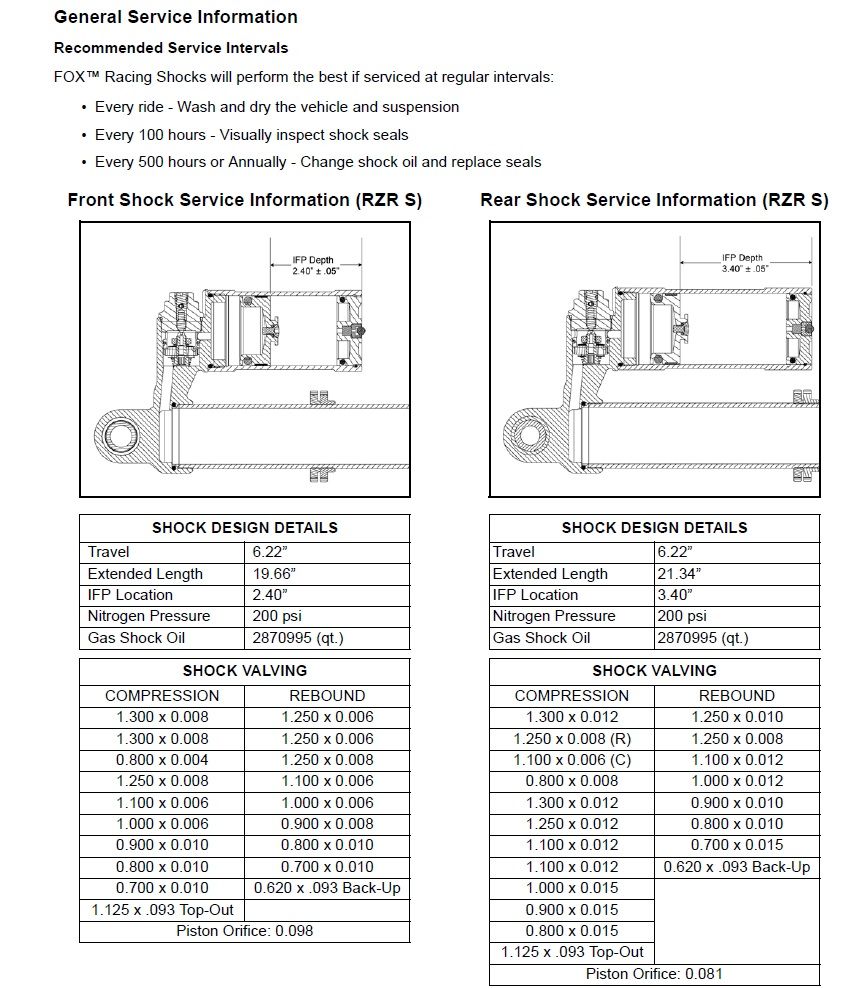

What is the ifp depth on a 2011 rzr s fox shock. i need a 2011 rzr-s service manual please

davsh

62 posts

·

Joined 2011

this is my first time rebuilding shocks and I came across this thread. I was curious as to why the ifp depth matters doesn't it move inside the shock? what keeps it in place if it doesn't? also its has a number next to the oil and the a qt in () is the number the type of oil and the qt how much it holds?

thanks in advance for the help

thanks in advance for the help

597 posts

·

Joined 2010

I'm also in my first try to rebuit my shocks but mine are walker evans ones and from what i read and Understand (someone can correct me if i'm wrong ) is the nitrogene is in there as an inert gas to keep the oil in the shock from boiling and cavitate when going up and down fast and the depth of the ifp is relative to the amount of oil in the shock ( less ifp depth in shorter front shocks and More for the rear) and it must have been calculated that way for best performance.

Inert gas is used instead of air because the pressure will be constant at any temp. like -40 to +200deg. f. For the ifp moving or not, it should be very little unless you're loosing pressure thru oil seal or shreader valve .

The oil wt is the vicosity and is again determined from the valving of the shock and the speed rate it has to go thru that valve in order to let the main shock piston go up and down a certain lenght at a certain pressure. Walker Evans shocks are using 10wt oil.

Hope you understand a bit more...

Inert gas is used instead of air because the pressure will be constant at any temp. like -40 to +200deg. f. For the ifp moving or not, it should be very little unless you're loosing pressure thru oil seal or shreader valve .

The oil wt is the vicosity and is again determined from the valving of the shock and the speed rate it has to go thru that valve in order to let the main shock piston go up and down a certain lenght at a certain pressure. Walker Evans shocks are using 10wt oil.

Hope you understand a bit more...

231 posts

·

Joined 2012

The IFP set depth controls the volume of oil and the volume of nitrogen in the shock.

1,031 posts

·

Joined 2010

Also the pressure of the nitrogen pushing against the ifp puts the oil under pressure. I believe it's the oil under pressure is was reduces cavitation and raises the boiling point.

Sent from my SGH-I727 using Tapatalk 2

Sent from my SGH-I727 using Tapatalk 2

818 posts

·

Joined 2010

When you are rebuilding the shock, make sure you cycle the shaft and listen for air. It does take some time to get the air out of the shock valves and shaft. I always pre charge my shocks with compressed air up to 150psi and cycle the shock again when it is fully put together to check for leaks and that the shaft will bottom out. Then drain the air and recharge with nitrogen.

Shock oil is rated by the viscosity index is what sets the heat it can take. Everyone has their own shock oil and viscosity rating. So a 10wt in Fox is different then a 10wt from WER shocks oil.

Shock PSI is what helps keep pressure on the oil so the shock valving doesn't cause cavitation which is air in the oil. The more air, stiffer the short choppy bumps will be. But the more air, the harder hits (jumps) it will be able to take without cavitation and fade.

Also, when you are taking your shocks apart. You need to inspec the shafts very well.

Shock oil is rated by the viscosity index is what sets the heat it can take. Everyone has their own shock oil and viscosity rating. So a 10wt in Fox is different then a 10wt from WER shocks oil.

Shock PSI is what helps keep pressure on the oil so the shock valving doesn't cause cavitation which is air in the oil. The more air, stiffer the short choppy bumps will be. But the more air, the harder hits (jumps) it will be able to take without cavitation and fade.

Also, when you are taking your shocks apart. You need to inspec the shafts very well.

1,862 posts

·

Joined 2009

Do a search for forum member Teamhog, conveniently has free service manual downloads posted in his signature .i need a 2011 rzr-s service manual please

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 3.2M

- members

- 152K

- Since

- 2007

A forum dedicated to Polaris RZR enthusiasts! A great place to find rides, meet people, and exchange ideas / parts/ rzrs!

Top Contributors this Month

View All

MNichols

1K Replies

craigstumph

132 Replies

FordTruckMan

98 Replies